Contents

- 1 Mining Terms

- 1.1 Adit or Drift

- 1.2 Afterdamp

- 1.3 Anvil Stone

- 1.4 Air gate

- 1.5 Anthracite

- 1.6 Bank

- 1.7 The surface of the mine, usually referring to the entrance to the pit Shaft. Banksman

- 1.8 Barrier

- 1.9 Basset or Basset Edge

- 1.10 Bell Pit

- 1.11 Blackdamp

- 1.12 Bords

- 1.13 Brattice

- 1.14 Broken (in the..)

- 1.15 Checkweighman

- 1.16 Corf

- 1.17 Datallers

- 1.18 District

- 1.19 Downcast

- 1.20 Firedamp

- 1.21 Fire Setting

- 1.22 Furnace

- 1.23 Gob, Goaf or Goave

- 1.24 Gate

- 1.25 Hammer Stone

- 1.26 Hutch

- 1.27 Inbye

- 1.28 Main gate

- 1.29 Onsetter

- 1.30 Outbye

- 1.31 Overman

- 1.32 Pillar

- 1.33 Putter

- 1.34 Road

- 1.35 Royalty

- 1.36 Shaft

- 1.37 Staple Shaft

- 1.38 Stoopings

- 1.39 Supply gate

- 1.40 Tail gate

- 1.41 Timbermen

- 1.42 Trapper

- 1.43 Upcast

- 1.44 Viewer

- 1.45 Waste

- 1.46 Whimsey Engine, Engine, Whim. Whim Gin.

Mining Terms

Adit or Drift

A tunnel driven from the surface underground or driven between seams. Used for pumping, transport, ventilation and

Afterdamp

Description given to the gases (noxious) remaining in a mine after an explosion, usually with a high content of Carbon Dioxide

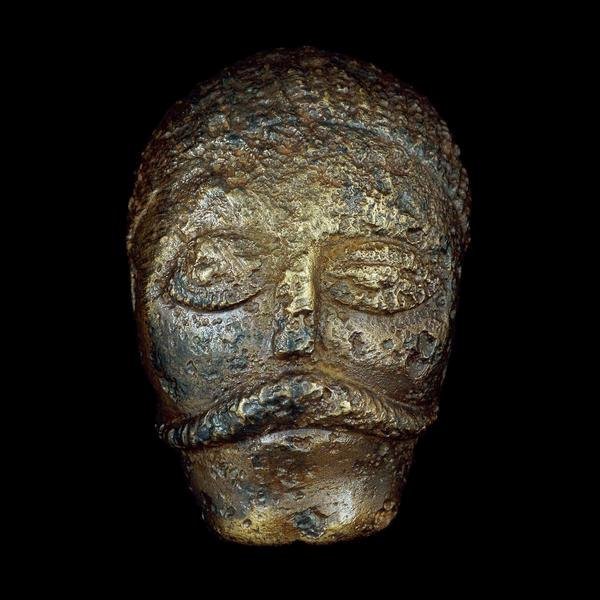

Anvil Stone

In early mining activities, ores were crushed by placing them on a flat anvil stone and hitting them with a hammer stone.

Air gate

The return roadway for stale air from the face to the surface.

Anthracite

Coal which is high in carbon with a small percentage of volatile matter

Bank

The surface of the mine, usually referring to the entrance to the pit shaft.

Banksman

The colliery official responsible for overseeing the loading and unloading of the pit cage at the surface (see Bank). The banksman was also in charge of signalling

Barrier

A portion of coal seam left intact between two collieries

Basset or Basset Edge

The place where a seam surfaces usually as a result of geological action on the strata.

Bell Pit

As the name suggests the mining operation produced a bell shaped pit. This was an early form of mining comprising of a shallow shaft into a seam. Coal was extracted and pulled up to the surface in baskets via a rope. A bell pit was complete when the pit was in immanent danger of collapse. A new shallow shaft would be sunk and the process started again. There will be many bell pits in an area.

Blackdamp

A mixture of carbonic acid gas and nitrogen

Blower

A discharge of firedamp under extreme pressure. (see firedamp)

Bords

The ‘gap’ left by mining coal in a ‘bord and pillar’ method. Describes the gap between pillars left to support the roof after mining. (see pillar)

Bords or stalls were a rectangular area of coal excavation and the pillars were the square columns of coal left for support. Usually worked in the shallow wet seams. The pillars were removed many years later by further mining operations.

Brattice

A division created in a mine shaft or tunnel which is used to control or direct the airflow in the mine. One side of the brattice would be the air flow intake and the other, the return

Broken (in the..)

Working ‘in the broken’ was a term used to describe actions in an existing (open) section of the mine as opposed to working on a new face or seam

Checkweighman

This was a very important job as he represented the interests of his fellow workers to the colliery management by checking the weight of the tubs of coal coming out of the mine. It was his job to keep a check on minerals extracted and to negotiate the true weight of coal coming out of the mine for which the men got paid. Management claiming a ton of coal could be between twenty one and twenty five hundredweight dependent on the amount of slack and small coals it contained, which they would not pay the miners for. The Checkweighman was elected by and financed by the miners.

Corf

A large wicker basket used to transport mined coal to the pit head and then to the surface. Term also sometimes used to describe the wheeled ‘tubs’

Datallers

Term used to describe workers paid strictly on a ‘Day rate’ basis

District

A number of working areas close together but in a separate portion of the coal to be worked

Downcast

The shaft down which fresh air passes into the workings of the mine. Most commonly also used as the winding shaft

Firedamp

The Miner’s description for the naturally occurring ‘marsh gas’ (methane) which results from the decay of vegetable matter. In certain critical volumes, mixed with air, firedamp is highly explosive.

Fire Setting

A very early extraction technique involving setting fires against ore laden rocks then rapidly cooling them with water. The rock fractures and is easily hammered off.

Furnace

A fire placed at the foot of the upcast shaft, the gas laden air from the mine would rise with the heat and create a circulatory ventilation process. Replaced in later years with powerful fans

Gob, Goaf or Goave

An area of the mine which has been previously mined and then used as a depository for waste from the workings. Such areas were normally left to collapse under the natural pressure of the roof

Gate

An underground roadway. From Old English ‘gate’ meaning path or footpath.

Hammer Stone

The earliest type of hammer, a hand size stone cobble perhaps 15cm long used to hit a wedge or chisel in order to separate rocks.

Hutch

Term used for a box container, later fitted with wheels, for the transportation of the coal to the surface (predominately a Scottish term)

Inbye

Direction of travel towards the centre of the mine

Main gate

The intake roadway taking fresh air through the mine and housing the conveyors for supplying the shaft with coal.

Onsetter

The official whose duty it is to ensure that the cage is properly loaded and unloaded at the foot of the shaft

Outbye

Direction of travel away from the centre of the mine

Overman

The Underground Manager (Oversman in Scotland)

Pillar

A pillar of coal left to support the roof above the workings

Putter

A man (or boy) who conveyed the tubs of coal from the face

Road

A main underground thoroughfare

Royalty

An area of coal leased to a colliery by the landowner

Shaft

Vertical entry to a mine latterly using powered winding gear and cages to supply, ride men and materials and take out coal. Formerly using a windlass or other manual means of winding. Usually sited in pairs. (Upcast and Downcast). Since Hartley Colliery Disaster 1862.

Staple Shaft

A vertical shaft in a mine which does not connect with the surface, usually between seams to prove coal measures.

Stoopings

Regional term for pillars

Supply gate

The roadway used to transfer materials to be used in mining operations.

Tail gate

As air gate.

Timbermen

The men employed to cut and install support timbers

Trapper

Person employed to open and close ventilation doors to ensure uninterrupted flow of air

Upcast

The shaft used, in conjunction with a furnace (or later, a fan) through which the expelled air (and gases) from the mine travel to atmosphere

Viewer

A mining engineer

Waste

Another term for Gob or Goaf

Whimsey Engine, Engine, Whim. Whim Gin.

Was a term first applied to a windlass and then to whim gins (Horse driven winding device). By the early 19th Century it was usually applied to steam winding engines (Fire Engines).